- Upload my file via Dropbox (which is also your login). I uploaded my EAGLE schematic and board file - other formats are also possible.

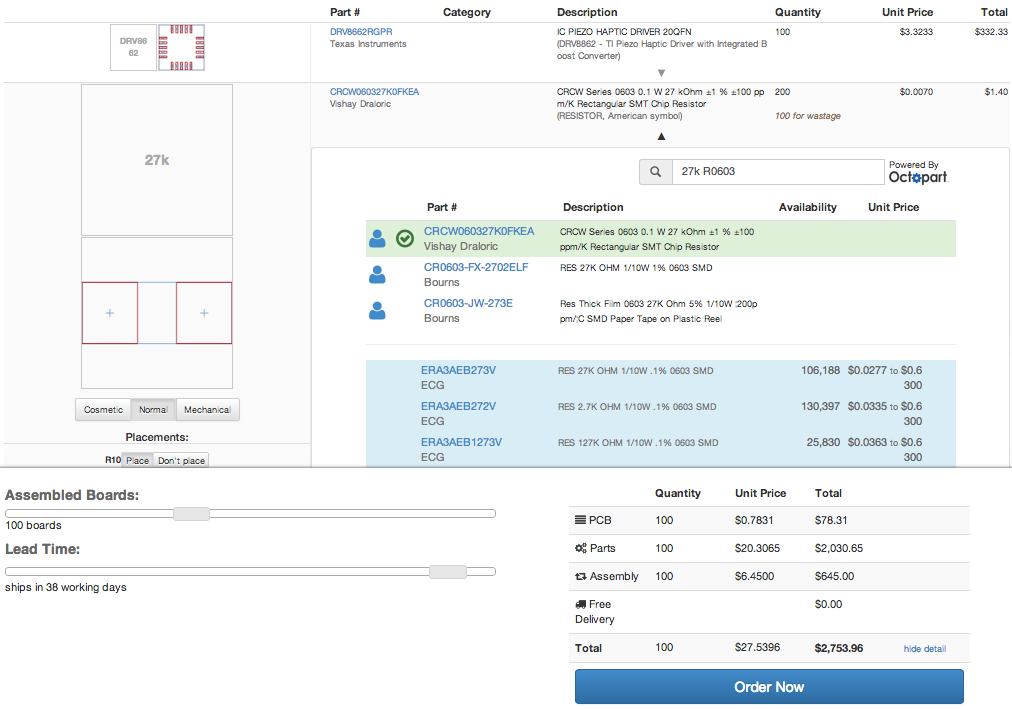

- Edit the BOM generated from the file and specify the acceptable components. For a resistor or other common components, there may be several candidates with varying price breaks and quality.

- Specify the quantity and lead time

- Look at the costs for PCB, parts and assembly

- Order!

Because the process is automated, I can easily generate a table like this:

| Lead time (days) | Quantity | PCB | Parts | Assembly | Total/board | Total |

|---|---|---|---|---|---|---|

| 33 | 10 | $3.49 | $32.60 | $10.00 | $46.09 | $460.80 |

| 31 | 50 | $8.70 | $23.48 | $7.90 | $40.08 | $2,003.74 |

| 36 | 100 | $5.80 | $20.31 | $6.45 | $32.56 | $3,255.65 |

| 36 | 500 | $3.58 | $18.20 | $2.45 | $24.23 | $12,030.51 |

| 48 | 1000 | $0.40 | $16.17 | $1.95 | $18.52 | $18,517.49 |

- The overall cost drops by about a factor of 2.5 when I reach 1000 units - a good chunk of this is the reduction in component cost by 2x that I observed last week. Between 10 and 100 I am seeing a drop of 30% in cost, and between 100 and 1000 I am seeing another 43% drop atop that.

- They are keeping the small volume PCB cost low - probably by batching and using an overseas supplier like I would. If I ask for a short lead time the cost of PCB skyrockets to over $100/board (e.g. a $1000 setup, more typical of a small batch turnaround) with a threshold around 30 days.

- Assembly costs are also quite reasonable, again with a relatively low setup cost for a small number of units. The $10/board is easily worth the time it took me to do my manual pick-n-place.

- The 30 day lead time make this service most useful for late stage prototyping and actual production.

- Wastage is a big deal at small volumes - for an order of 10, you are usually paying for at least 100 components in the leader of the reel. I can see that it may make sense to make my minimum order threshold at least 100 units.

Its a friendly arbitrage scheme, as I wouldn't have access to the components at small volumes, and they take care of the hassle of keeping track of the reels, etc. and also take away a lot of technical (e.g. using proven land patterns) and supply chain risk.

Having this information easily available eases many of my worries and helps me direct my design efforts. I can get answers quickly to several questions:

- What are the most expensive components in both small and large volume? (the LCD display, the rotary edge wheel encoder, and the DRV8662 chip)

- Are there substitutes for these components, or a cheaper alternative design (e.g. using a codec chip instead of building my own volume control/mixing networks)?

- At what point should I switch from hand-building boards to using assembly service? What is the cost/time trade-off?

- How long will I need to wait; what will it cost me if I need things faster - or delay and work on marketing etc?

I'm looking forward to doing my next design and seeing how much I can influence the cost of the board! I've also started thinking of testing simple designs built around one or two chips or ideas, and seeing how inexpensively they could be brought to market.

Happy designing!

RSS Feed

RSS Feed